As the first of its kind the SpiroScout simultaneously measures flow and gas density providing all the necessary information about the volume and gas exchange from one single measurement.

- Realtime BTPS correction, drift free, high accuracy

- Different options available such as rhinomanometry, oscillatory resistance, capnovolumetry, emphysema test, dead space analysis

- No volume calibration and no warm-up time necessary

- Perfectly hygienic concept optimising workflow and patient safety

- No perceptible resistance and more comfort for the patients

Technical elegance for precise measurements and economic workflow

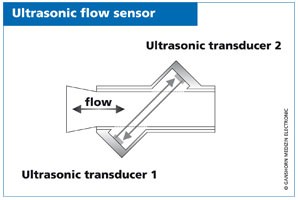

Ultrasonic Spirometry – the quick ultrasonic measurement method for direct and precise flow determination.

No substitute parameters for flow (e.g. differential pressure, temperature or turbine) necessary. Direct flow measurement based on digital measurement technology. High measurement resolution due to 1,000 individual measurements per second – developed and patented by GANSHORN.

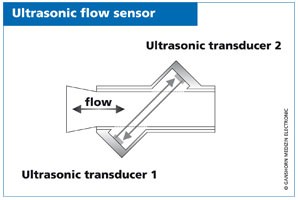

Measurement principle

Two diagonally opposing piezo-elements send and receive alternatively ultrasonic waves. Without any flow the transit time of the ultrasound waves is the same in both directions. Flow moving the air inside the tube will accelerate the waves in one direction and slow them down in the other. The higher the difference between go and return, the higher the flow. All other factors (gas properties, humidity, temperature) are the same for both directions and cancel each other out.

- No changes of measurement values due to changing ambient conditions or breathing humidity.

- Calibration free during running operation – an advantage that pays off daily.

- No erroneous measurements due to wrongly or non calibrated pneumotachs.

- The high resolution of 1,000 measurement points per second is a substantial condition for reliability.

- Determination of flow and all derived parameters as volume or also the resistance during the Bodyplethysmography measurement.

- No perceptible resistance in the breathing tube obstructs the respiration of the patient – especially helpful for patients with limitations.

- Reliable and durable.

- Breathing tube made of anodized aluminium and stainless steel.

- Suitable for any cleaning plan, not only cold chemical disinfection, but also thermal cleaning (sterilisation, autoclaving) possible.

- Easy and quick changing of the breathing tube without the assembly of several pieces.

- Also suitable for disposable bacterial and viral filters.